Package Engineering Center

Combining expertise with technology

ISTA certification

Our Package Engineering Center – located in the city of Nagoya, Aichi Prefecture – received ISTA certification in May 2015. We can thus test packaged freight for compliance with ISTA standards and issue official ISTA test results for specific packaging solutions.

ISTA-compliant standards for which testing is offered

1A,1B,1C,1D,1G,1H,2A,2B,2C,3A,3B,3F,

6-AMAZON.com-Over Boxing,

6-AMAZON.com-SIOC Type A,Type B,Type D,

6-Fedex-A,6-SAMSCLUB,7D

Lab equipment

The equipment available at our Package Engineering Center can handle a wide variety of procedures to meet client requirements.

Freight evaluation

Shock tester, drop type

Purpose

To identify external forces that may damage products.

Procedure

- Generate a "damage boundary curve " that draws boundary lines to show where products have been damaged.

- Table dimensions:

- 945 x 1,153 mm

- Maximum sample package weight:

- 454 kg

- Output waveform:

- Sinusoidal, Square

- Testing standards:

- JIS Z 0119, ASTM D 3332

Drop test system

Purpose

Check whether drop impact damages products or causes problem with packages.

Procedure

- To apply drop impact to package freight simulating loading and load shifting during transportation.

- Maximum sample package weight:

- 79 kg

- Maximum depth:

- D910 mm

- Drop height:

- 280 to 1,830 mm

- Vertical drop test system:

- For drop testing large products.

- Testing standards:

- JIS Z 0203, ISO 2248

Vibration test system

Purpose

Check whether vibration damages or causes fatigue failure in products or causes problems with packaging.

Procedure

- To apply vibration stress encountered by packaged freight in transportation environments.

- Table dimensions:

- 1,500 x 1,500 mm

- Vibration frequency:

- 1 to 2,200 Hz

x / y / z axes

Capable of applying vibration of sinusoidal and random waveforms. - Maximum sample package weight:

- 1,000 kg

- Testing standards:

- JIS Z 0232, ISO 8318・13355

Compression test system

Purpose

To determine the effect on cargo when packaging (container) and/or pallet are subjected to compression, and to facilitate future design that ensures appropriate strength.

Procedures

- Check the compressive strength of corrugated fiberboard, wood and steel containers.

- Check that vertical compressive strength and bending strength of pallets are adequate.

- Table dimensions:

- 1,300 x 1,300 mm

- Maximum height of sample:

- 1,800 mm

- Maximum sample package weight:

- 98 kN

- Testing standards:

- JIS Z 0212, ISO 12048

Material evaluation

Corrugated fiberboard – Bursting tester

Purpose

To determine the quality of corrugated cardboard and check whether it has sufficient strength.

Procedures

- Check the burst strength of fiberboard – linerboard and corrugating mediums – and corrugated fiberboard.

- Check whether the specified materials have been used to make the cardboard.

- High pressure:

- For linerboard

- Low pressure:

- For corrugating medium

- Testing standards:

- JIS P 8131・P 8112, ISO 2758

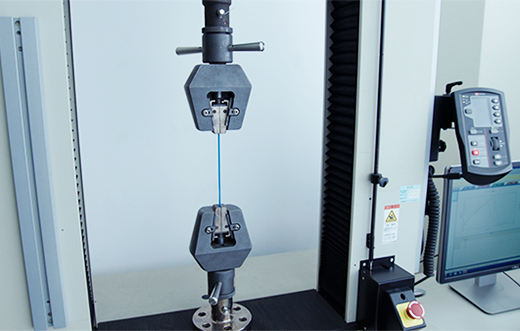

Tensile and compression test system

Purpose

To make a comprehensive determination of the strength of packing materials in response to flexing, compression and tension.

Procedures

- Check properties such as bending, compressive and tensile strength unique to the material.

- Check vertical and horizontal compressive strength of corrugated fiberboard.

- Maximum sample package weight:

- 49 kN

- Tests:

- compression test, tensile test

- Controls:

- table speed control, load control

- Testing standards:

- JIS P 8126・P 8113・Z 0401, ISO 1924・1974・3037

Cushioning performance test system

Purpose

To create cushioning design guidelines for packaging materials.

Procedures

- Check the cushioning performance of packaging material.

- Estimate the degree of impact on products based on drop conditions and the status of packaging.

- Drop weight:

- 0.9 to 50 kg

- Static stress:

- 0.5 to 78.5 kPa

- Testing standards:

- JIS Z 0235, ISO 4651

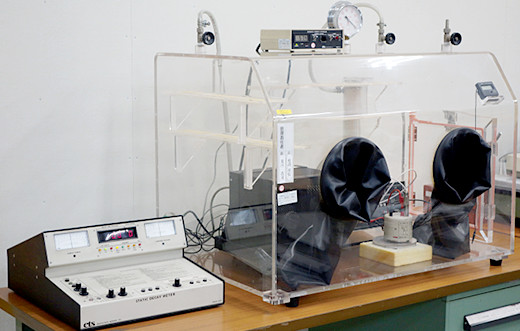

Static electricity test system

Purpose

To evaluate the electrical performance of packing materials and to put this data to use in finding ways to counter static electricity.

Procedures

- Check electrical properties (electrical conductivity) of material.

- Check whether material is processed to protect against static electricity.

[Volume resistivity test system]

- Applied voltage:

- ±5 kV

[Surface resistivity test system]

- Applied voltage:

- 10, 100, 500 V

- Resistance range:

- 200M to 2T Ω

- Testing standards:

- EIA 541, IEC Pub93, MIL B 81705C

Temperature / humidity testing chamber

Purpose

To check / evaluate the insulation effectiveness of packing materials in a temperature / humidity-controlled environment.

Procedures

- Reproduce the desired environment (temperature / humidity).

- Keep packing materials under fixed temperature / humidity conditions (equilibrium state) as preparation for other tests.

- Capacity:

- 12,500 ℓ

- Inner dimensions:

- 3,020 x 2,100 x 1,970 mm

- Temperature range:

- -30 to +80 ℃

- Humidity range:

- 10% to 95% RH

- Testing standards:

- JIS Z 0203, ISO 2233