Consideration for the planet’s environment is a core facet of Mitsubishi Electric Logistics’ operations. Our goal is to achieve “Eco Logistics”. In striving to keep our activities as ecological as possible, we focus on three key areas: shipping and delivery, our warehouses, and the packaging we use.

Eco Shipping

Mitsubishi Electric Logistics has taken a number of steps to achieve more ecological transport and delivery of goods. We have introduced low-emission vehicles such as hybrid and CNG trucks, adopted technology to enable more efficient driving, and implemented a modal shift in method of transport and vehicle loading efficiency. Together these measures are enabling us to use less fuel, generate less CO2, and reduce NOx and PM emissions.

Hybrid, CNG Vehicles

We have added fuel-efficient, low-emission hybrid1 and CNG2 vehicles to our fleet of transport and delivery trucks.

All our delivery trucks are also equipped with a vehicle operations management system that analyzes speed, position, route, acceleration and other information to help drivers operate their vehicles in a safe and more fuel-efficient way. Such “eco-driving” technologies are also helping to reduce environmental impact.

- 1Hybrid Vehicle: a vehicle that uses both a diesel engine and an electric motor for power. Hybrid technology boosts fuel efficiency and reduces CO2 emissions.

- 2CNG Vehicle: a vehicle fueled by compressed natural gas as fuel. CNG engines produce no particulate matter, and dramatically reduce CO2, NOx and hydrocarbon emissions.

Modal Shift

In addition to achieving better load ratios in our trucks through the use of more efficient loading and stacking techniques, we are implementing a modal shift toward greater use of rail transport, which has less environmental impact than trucking.

We have introduced specially designed rack containers that make one-stop international logistics more practical. The use of these containers has also made possible small lot (single 12-foot container) deliveries to distribution centers throughout Japan.

Example:

Transporting freight from the Kansai Region to the Kanto Region

Eco Warehouse

We are implementing a variety of measures to decrease the amount of electricity used at our warehouses. We have set up photovoltaic systems on top of warehouse buildings to generate power, and have begun setting up ice thermal-storage air conditioning systems to reduce power demands. And we are using ultra lightweight moss for rooftop greening to help block heat from the sun.

We are also switching to more highly efficient electrical power equipment, as well as high-efficiency LED lighting. LED lighting creates less heat, uses less energy and generates less CO2.

To closely manage power usage at our buildings we introduced a power demand monitoring system that monitors power use, identifies areas of waste or potential reduction, and reduces peak power demand.

Photovoltaic System

Roof Greening

LED Lighting

Power Demand Monitoring

ISO14001

In addition to Mitsubishi Electric Corporation manufacturing plants in which we have an office or center, Mitsubishi Electric Logistics Corporation has achieved ISO14001 certification at 22 of its own business sites and logistics centers across Japan.

Eco Packaging

Through promoting the 3Rs (Reduce, Reuse, Recycle) in our packaging activities, Mitsubishi Electric Logistics is conserving resources and helping to achieve a recycling-based society.

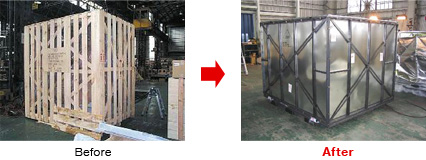

Example 1

Switching from the use of wooden packing crates to steel containers

Through promoting the 3Rs (Reduce, Reuse, Recycle) in our packaging activities, Mitsubishi Electric Logistics is conserving resources and helping to achieve a recycling-based society.

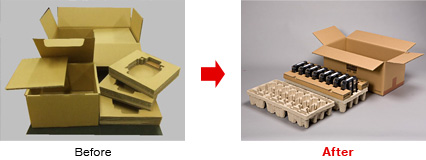

Example 2

Switching from the use of cardboard to molded pulp packing, which reduces packaging materials costs by 40%